What Makes Gun Safes Fireproof

What makes gun safes fireproof? What features must a gun safe have to be able to withstand high heat and fire damage? In short it’s all about the right materials and smart design.

The use of fire-resistant materials like steel, gypsum, ceramic fibers, concrete, Drylight and Palusol is what makes gun safe fireproof. A layered construction makes them safes even more effective.

While no safe is 100% fireproof, as prolonged exposure to fire will eventually penetrate any barrier, these technologies significantly extend the protection time for your valuables against extreme temperatures. Want to know more how these elements work together in a gun safe? We explain everything.

Key Fire-resistant Materials In Gun Safes

Fireproof gun safes use specialized materials to guard against fire:

- Steel: Acts as the safe’s backbone, providing strength and heat resistance. The effectiveness of steel in preventing heat damage depends on its thickness and grade.

- Gypsum Board: Embedded with water molecules, gypsum board releases steam when heated, significantly lowering the internal temperature of the safe during a fire.

- Ceramic Fibers: Known for exceptional heat insulation, ceramic fibers shield the safe’s contents from extreme temperatures, maintaining a safer internal environment.

- Cement and Concrete: These materials are adept at absorbing and spreading out heat. Including them in a safe’s construction enhances its ability to protect against fire damage.

- Perlite and Vermiculite: Light yet powerful insulators, they expand when heated, effectively sealing off the spread of flames and smoke within the safe.

Design & Build Of Fireproof Safes

The effectiveness of fireproof safes is based in big part on their design and construction specifics:

- Layered Construction: These safes use a combination of fire-resistant materials in their walls, such as steel, gypsum board, and ceramic fibers. This setup acts as a barrier against heat and smoke, keeping the interior cool.

- Reinforced Doors: Doors are made to fit tightly against the frame, with edges designed to prevent heat ingress. Heat-activated seals expand to fill gaps, blocking smoke and flames.

- Insulation Placement: Insulation is strategically placed in the most heat-vulnerable areas, like the safe’s sides and door. This ensures more efficient heat resistance where it’s needed most.

- Durable Hinges: Hinges are constructed to not only support the weight of the door but also to resist warping or melting at high temperatures, keeping the door securely in place during a fire.

- Advanced Locking Mechanisms: Locking systems are engineered to remain functional after exposure to fire, enabling access to the safe’s contents afterwards.

Thermal Expansion: How it Works in Safes

Thermal expansion plays a key role in the fire resistance of gun safes. When exposed to high temperatures, materials used in safes, such as steel and insulation, expand. This expansion can affect the safe’s structure and integrity.

But fireproof safes are engineered to accommodate thermal expansion without compromising their protective qualities. For instance, gaps within the insulation allow for expansion without damaging the safe’s outer structure.

Locking mechanisms are designed to withstand the effects of thermal expansion, ensuring they remain operational or locked as needed during and after exposure to fire.

The Role of Seals and Gaskets in Fireproofing

Seals and gaskets are essential for making gun safes fireproof. Here’s how they work:

Heat-Activated Seals: These seals expand when they get hot. This expansion fills up gaps around the door, keeping smoke and fire out.

Smoke Protection: By expanding, these seals also stop smoke from getting inside. Smoke can damage the safe’s contents, so this protection is key.

Maintaining Integrity: The seals help the safe stay sealed and intact during a fire. This means the contents are more likely to survive unharmed.

Types of Insulation

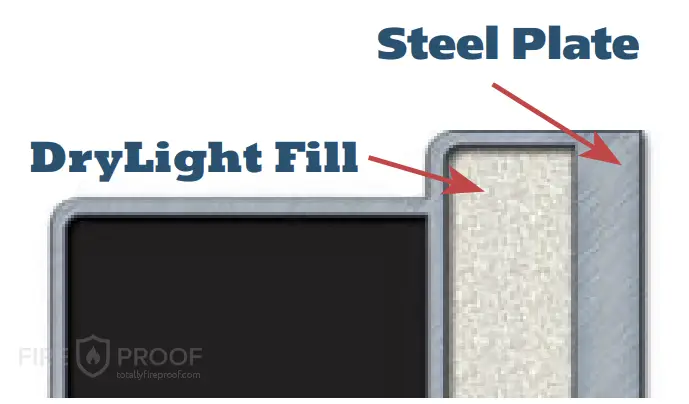

Different insulation materials protect gun safes from fire in specific ways. Take DryLight Technology for example. This insulation is like a lighter version of concrete. It surrounds the inside of the safe, acting as a barrier against heat. For example, if a fire reaches 1000°F outside, DryLight helps keep the inside much cooler, safeguarding your guns and valuables.

Then there’s also Palusol Seals. Imagine a strip around the safe door that puffs up like a marshmallow in the heat. When a fire hits, these seals expand to many times their size, filling gaps to stop fire and smoke from getting in.

Optimal Placement for Best Fire Protection

Where you place a fire-resistant gun safe in your home can significantly affect its ability to protect contents in a fire. Here are practical tips:

- Away from High Heat Areas: Avoid placing the safe near kitchens or furnaces where fires are more likely to start.

- Ground Level Placement: Heat rises, so keeping your safe on the ground floor or in a basement can reduce exposure to intense heat in a fire.

- Interior Locations: Choose an interior location away from exterior walls and windows to minimize heat transfer and exposure to direct flames.

- Near Fire Exits: While keeping the safe away from high-risk areas, placing it near an exit can make it easier for firefighters to protect or retrieve it in an emergency.

Fire Ratings & Certifications

Fire ratings and certifications provide a standardized measure of a gun safe’s ability to withstand fire.

Fire Rating indicates the length of time a safe can withstand a specific temperature without the internal temperature rising above a set point. Usually the inner limit is 350°F, which is considered safe for most valuables.

Testing Agencies: Organizations like Underwriters Laboratories (UL) test safes under simulated fire conditions to assign these ratings. For example, a UL rating of 1-hour at 1700°F means the safe can keep its contents below 350°F for at least one hour at external temperatures up to 1700°F. Read more about UL Ratings in our Guide.

If the manufacturer does the testing internally without using the services of third party agencies, then any rating they assign to a safe is considered as “Factory tested”. The question if this rating reliable and trustworthy is a different issue altogether. It mainly depends on the reputation of the brand and real reviews.

Conclusion

Effective fire protection in gun safes comes down to fire-resistant materials, and the designs that heavily uses layered construction. While perfect fireproofing is unattainable, these elements significantly enhance a safe’s resistance to fire, buying crucial time during emergencies. In the end all this gives you time to react to fire emergencies as well as protects your guns and other expensive items.